Benefits of Water Jet Cutting Over Traditional Methods

Glass is a delicate material, and cutting it requires precision and expertise. Traditional methods of glass fabrication have been used for a long time, but technology has brought about a new way to cut glass with ease: water jet cutting. Water jet cutting offers several advantages over traditional methods that make it a popular choice in the industry today. In this blog post, we will explore the benefits of hiring a water jet-cutting service for glass fabrication.

Advantages of water jet cutting over traditional methods

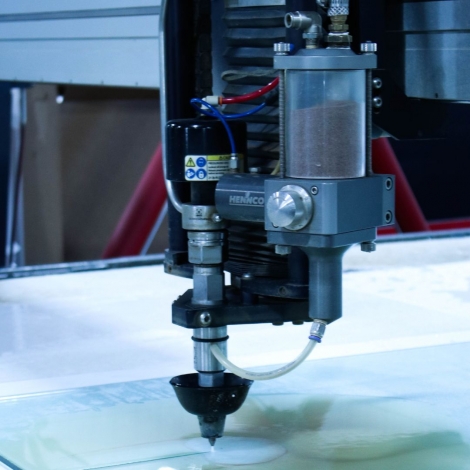

- Unlike traditional methods like sawing and grinding, water jet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through hard surfaces easily.

- One of the major advantages of water jet cutting is its precision. The technology allows for accurate cuts without any distortion or heat damage, which is common with other methods. This level of precision ensures that there are fewer errors during production and reduces waste significantly.

- There are more benefits to relying on a water jet cutting service for cutting glass for fabrication. With traditional methods, creating intricate designs in glass would require several steps and tools, which could lead to errors due to human interference. Water jet cutting eliminates this problem by allowing for computer-aided design (CAD) accuracy in producing even the most complicated shapes.

Conclusion

Water jet cutting has revolutionized the way the glass fabrication process is carried out. Its ability to cut through various materials, including thick glass sheets with high precision and accuracy, has made it an invaluable tool in this industry. You can rely on All Team Glass & Mirror Ltd. if you are looking for a water jet-cutting service provider. We offer water jet cutting of the highest quality at reasonable rates. We are also one of the leading names when it comes to glass fabrication in Toronto. Contact us today to learn about everything we can do for you.