Blog

Latest News & Articles

Glass Etching Explained: Process and Benefits

February 27, 2026

Architectural Glass Solutions for Contemporary Projects

February 19, 2026

Custom Shower Glass Explained: Design and Function

February 13, 2026

Why Custom Glass Shower Doors Are the Perfect Upgrades

February 10, 2026

Architectural Glass: Types, Uses, and Design Benefits

January 29, 2026

Practical Applications of Tempered Glass in Architecture

January 26, 2026

What is Glass Sandblasting and How Does It Work?

January 20, 2026

How Decorative Sandblasting Enhances Glass Interiors

January 12, 2026

Why Tempered Glass Is the Preferred Choice for Modern Spaces

January 05, 2026

Why a Reliable Glass Supplier Matters in Construction

December 29, 2025

What Should You Look for in a Reliable Glass Manufacturer?

December 23, 2025

Choosing the Right Laminated Glass Supplier

December 16, 2025

Benefits of Working with a Top Glass Manufacturer

December 11, 2025

Why Custom Glass Shower Doors Are Ideal for Modern Bathrooms

November 27, 2025

Tempered or Laminated? Clarifying the Right Choice in Safety Glass

November 24, 2025

The Real Impact of Architectural Glass on Interiors

November 12, 2025

All Team Glass: Trusted Laminated Glass Manufacturers

November 11, 2025

4 Reasons Why All Team Glass Is a Trusted Glass Manufacturer

October 28, 2025

How Laminated Glass Enhances Security and Design

October 20, 2025

Why Choose Custom Tempered Glass For Homes?

October 15, 2025

3 Reasons To Upgrade To Custom Glass Shower Doors

September 25, 2025

Impressive Facts About Tempered Glass

September 18, 2025

The Role of Custom Tempered Glass in Modern Interior Design

September 09, 2025

Top Residential Applications of Glass Sandblasting

September 03, 2025

Tempered Glass vs. Regular Glass: What Contractors Must Know

August 27, 2025

Enhancing Building Safety With Tempered Laminated Glass

August 20, 2025

Frameless Custom Glass Shower Doors For Spotless Finish

August 15, 2025

Applications of Laminated Glass In Modern Architecture

August 05, 2025

̧Enhancing Protection With Safety Glass

July 31, 2025

Architectural Glass: Reliable and Versatile

July 16, 2025

Custom Shower Glass For Improved Aesthetics

July 11, 2025

Glass Sandblasting And Its Benefits

June 27, 2025

Discussing The Wonders of Architectural Glass

June 23, 2025

Elevate Bathrooms With Custom Glass Shower Doors

June 16, 2025

What Makes Laminated Glass Useful?

June 10, 2025

Common Benefits Of Tempered Glass Panels

June 03, 2025

Custom Shower Glass For Seamless Aesthetics

May 28, 2025

A Quick Guide To Understanding Safety Glass

May 20, 2025

Architectural Glass For Elevated Designs

May 13, 2025

Custom Etched Glass For Enhanced Visual Appeal

May 02, 2025

Understanding Tempered Glass And Its Applications

April 23, 2025

The Many Applications of Laminated Glass

April 18, 2025

Architectural Glass: An Exquisite Design Element

April 08, 2025

Importance of Doing Business With Experienced Glass Suppliers

April 01, 2025

Importance Of Sourcing Quality Glass Shower Doors In Toronto

March 27, 2025

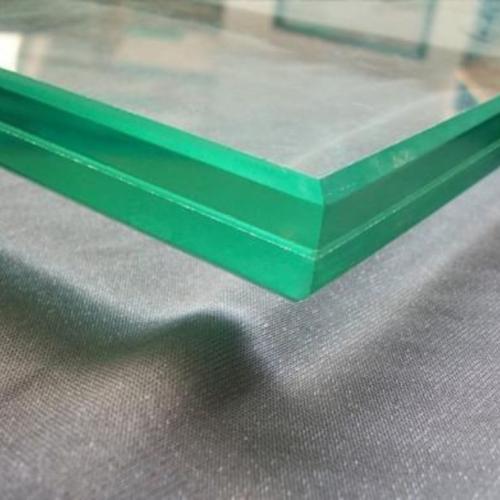

A Quick Guide To Laminated Glass

March 20, 2025

Trust Custom Tempered Glass For Elevated Designs

March 13, 2025

The Excellent Qualities of Architectural Glass

February 28, 2025

Custom Glass Shower Doors From All Team Glass & Mirror Ltd.

February 24, 2025

Achieving Perfection With Custom Tempered Glass

February 14, 2025

The Ultimate Design Material: Tempered Laminated Glass

February 10, 2025

3 Tips To Make Custom Shower Glass More Appealing

January 30, 2025

A Quick Guide To Tempered Safety Glass

January 24, 2025

Custom Glass Shower Door to Enhance Space in Small Bathrooms

January 15, 2025

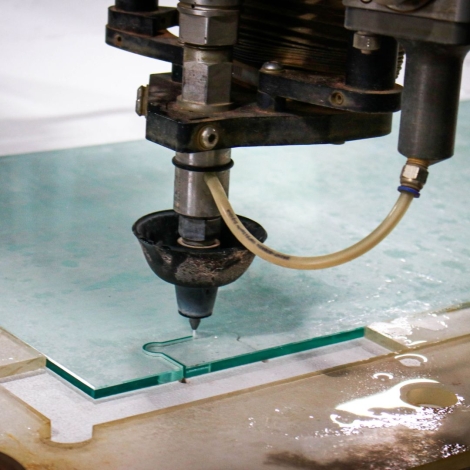

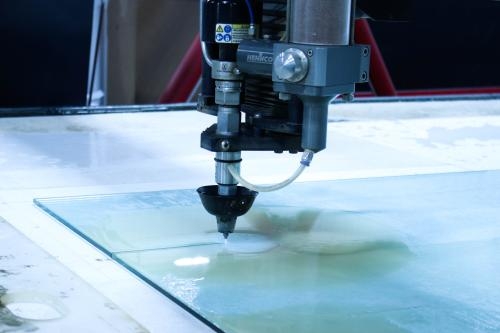

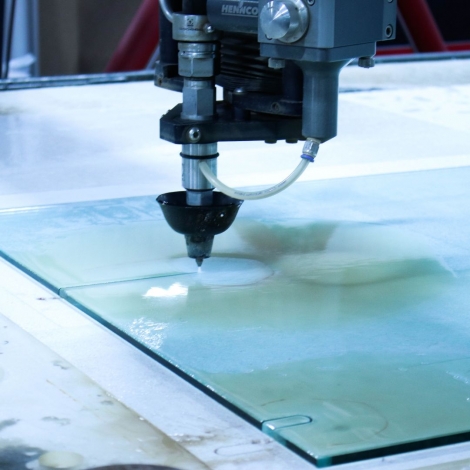

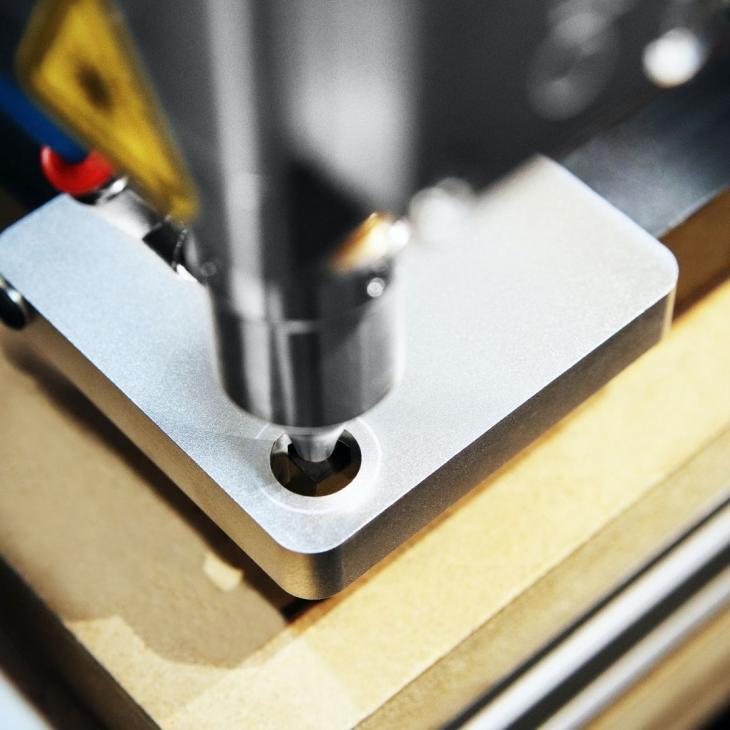

Benefits of Water Jet Cutting Service For Glass Fabrication

January 08, 2025

Dependable Safety Glass From All Team Glass & Mirror Ltd.

January 02, 2025

Investing in Custom Etched Glass For Privacy And Aesthetics

December 27, 2024

How To Spot Good Tempered Laminated Glass?

December 19, 2024

Benefits of Glass Etching and Its Applications

December 11, 2024

What to Expect When Investing in Custom Shower Glass?

December 03, 2024

Elevating Design With Glass Etching

November 26, 2024

Why is Laminated Glass A Game-Changer In Modern Architecture?

November 13, 2024

Why Going For Shower Glass Panels Is A Foolproof Idea

November 11, 2024

Common Applications of Tempered Laminated Glass

November 01, 2024

3 Reasons To Choose Our Custom Tempered Glass

October 29, 2024

3 Reasons To Choose Custom Glass Shower Panels

October 21, 2024

Understanding The Benefits of Safety Glass

October 16, 2024

All You Need To Know About Glass Sandblasting

October 01, 2024

3 Desirable Features of Laminated Safety Glass

September 25, 2024

3 Tips To Choose The Right Custom Glass Shower Doors

September 23, 2024

3 Reasons To Source Custom Shower Glass

September 10, 2024

Discussing The Different Types of Glass Etching

September 03, 2024

3 Reasons We Are The Best Glass Suppliers in Toronto

August 26, 2024

3 Reasons Glass Etching Is Highly Sought After

August 21, 2024

3 Reasons To Choose Our Glass Sandblasting Services

August 13, 2024

3 Qualities of Tempered Glass

July 30, 2024

All You Need To Know About Tempered Laminated Glass

July 23, 2024

3 Reasons to Choose Custom Glass Shower Doors

July 18, 2024

All You Need To Know About Safety Glass

July 12, 2024

3 Extraordinary Benefits of Tempered Glass Panels

July 03, 2024

3 Reasons To Avail Our Water Jet Cutting Service

June 28, 2024

3 Benefits of Glass Sandblasting

June 19, 2024

Peak Elegance And Functionality: Custom Glass Shower Doors

June 13, 2024

Application Of Architectural Glass in Interior Design

June 04, 2024

3 Benefits of Laminated Safety Glass

May 30, 2024

The Art of Glass Sandblasting

May 21, 2024

Glass Etching By All Team Glass & Mirror Ltd.

May 10, 2024

3 Uses of Tempered Glass Panels

April 29, 2024

All Team Glass & Mirror: The Best Glass Supplier in Toronto

April 23, 2024

Why Is Architectural Glass So Highly Sought After?

April 16, 2024

3 Qualities To Look For In Laminated Glass Manufacturers

April 09, 2024

Decoding The Popularity of Architectural Glass

April 02, 2024

Applications of Custom Tempered Glass

March 21, 2024

The Benefits of Glass Sandblasting For Custom Etching

March 14, 2024

3 Qualities of Tempered Laminated Glass

March 06, 2024

Applications of Glass Sandblasting

February 29, 2024

Why Source Top-Quality Safety Glass From Us?

February 23, 2024

Trust Us For The Best Custom Glass Shower Doors in Toronto

February 16, 2024

Glass Shower Doors in Toronto by All Team Glass & Mirror Ltd

February 09, 2024

Understanding The Art of Glass Sandblasting

January 29, 2024

Understanding Quintessential Features Of Safety Glass

January 23, 2024

The Significance of Architectural Glass In Our Times

January 12, 2024

Transforming Bathrooms With Custom Glass Shower Doors

January 03, 2024

Decoding Flawless Water Jet Cutting Service

January 02, 2024

Harnessing the Power of Natural Light with Architectural Glass

December 22, 2023

Effective Soundproofing With Laminated Glass

December 07, 2023

Functionality And Elegance Of Custom Glass Shower Doors

December 01, 2023

The Use of Laminated Glass As Store Fixtures

November 24, 2023

The Benefits of Glass Sandblasting Beyond Aesthetics

November 14, 2023

Exploring the Potential of Water Jet Cutting For Glass Fabrication

November 07, 2023

Elevating Bathrooms With Frameless Glass Shower Doors

October 26, 2023

Practical Nuances of Custom Glass Shower Doors

October 20, 2023

Types of Laminated Glass from All Team Glass & Mirror

October 16, 2023

Achieving Customization With Glass Sandblasting

October 10, 2023

Architectural Glass - The Focal Point of Modern Constructions

September 29, 2023

Why Custom Glass Shower Doors Are Worth the Investment

September 26, 2023

The Intricacies of Glass Sandblasting

September 19, 2023

Enhancing Security With Laminated Glass

September 11, 2023

3 Impeccable Features of Custom Glass Shower Doors

August 25, 2023

The Many Uses of Tempered Glass Panels

August 17, 2023

Exploring the Role of Laminated Glass in Modern Architecture

August 10, 2023

Explaining The Process of Glass Sandblasting

August 08, 2023

Understanding The Process of Architectural Glass Design

August 02, 2023

The Applications of Laminated Glass in Interior Design

July 28, 2023

Add Elegance To Your Bathroom With Custom Glass Shower Doors

July 18, 2023

Elevating Glass Designs With Glass Sandblasting

July 12, 2023

Exploring The Beauty and Functionality of Architectural Glass

July 04, 2023

The Importance of Safety Glass in Modern Architecture

June 28, 2023

The Role of Tempered Glass Panels in Construction

June 13, 2023

How Laminated Glass Enhances Soundproofing in Buildings

June 07, 2023

Exploring the Sustainability Benefits of Architectural Glass

May 25, 2023

Benefits of Water Jet Cutting Over Traditional Methods

May 18, 2023

What is Glass Sandblasting and How Does it Work?

May 11, 2023

How Are Custom Glass Shower Doors Manufactured?

May 08, 2023

Why Are Custom Glass Shower Doors Popular?

April 20, 2023

Explaining The Rising Popularity of Architectural Glass

April 17, 2023

The Purpose of Glass Sandblasting?

April 13, 2023

All You Need To Know About Laminated Glass

April 06, 2023

Common Types of Architectural Glass

March 31, 2023

Is Hiring a Water Jet Cutting Service a Good Idea?

March 24, 2023

How Are Tempered Glass Panels Manufactured?

March 23, 2023

Everything You Need To Know About Glass Sandblasting

March 10, 2023

Are Custom Etched Glass Windows a Good Choice?

February 24, 2023

Avail Water Jet Cutting Service From All Team Glass & Mirror

February 21, 2023

Commercial Applications of Tempered Glass Panels

February 10, 2023

Is Architectural Glass Eco-Friendly?

February 06, 2023

Here's Why Custom Glass Shower Doors Are A Huge Hit

January 31, 2023

Here Is Why You Can Rely On Water Jet Cutting Service

January 27, 2023

Applications of Tempered Glass Panels

January 23, 2023

Benefits of Architectural Glass Partitions For Your Home

January 13, 2023

How Is Architectural Glass Beneficial For The Environment?

December 30, 2022

Tempered Glass Panel Maintenance Tips

December 20, 2022

Elevate Your Bathroom With Custom Glass Shower Doors

December 14, 2022

Reasons Why Architectural Glass is Sought-After

December 05, 2022

Everything You Need To Know About Custom Etched Glass

November 30, 2022

A Complete Guide To Water Jet Cutting Service

November 28, 2022

Everything You Need To Know About Custom Glass Shower Doors

November 18, 2022

How To Maintain Architectural Glass?

November 07, 2022

Water Jet Cutting And The Glass Industry

October 28, 2022

A Brief Guide To Sourcing Quality Tempered Glass Panels

October 24, 2022

How To Spruce Up Your Home With Architectural Glass

October 20, 2022

3 Signs Of Quality Glass Manufacturers

October 12, 2022

Steps Involved In Making Tempered Glass Panels

September 30, 2022

Tempered Glass Panels Installation: 3 Safety Tips

September 28, 2022

4 Reasons To Go For Frameless Custom Glass Shower Doors

September 19, 2022

3 Types of Architectural Glass Lamination

September 15, 2022

Common Techniques Used In Glass Fabrication

September 09, 2022

Features And Benefits Of Custom Etched Glass

August 31, 2022

3 Common Uses Of Tempered Glass Panels

August 29, 2022

4 Types Of Architectural Glass

August 11, 2022

3 Significant Benefits Of Water Jet Cutting Service

August 08, 2022

3 Applications Of Custom Etched Glass

July 29, 2022

3 Industries Using Water Jet Cutting Service

July 26, 2022

The Uses Of Decorative Sandblasting In Glass Fabrication

July 18, 2022

How To Transform Your Abode With Architectural Glass

July 07, 2022

3 Signs Of Good Tempered Glass Panels

June 27, 2022

Easy Cleaning And Maintenance Tips For Safety Glass

June 20, 2022

3 Qualities To Look For In Glass Manufacturers

June 13, 2022

An Overview Of Glass Manufacturers

June 09, 2022

How Is Architectural Glass Made?

May 30, 2022

2 Advantages of Using Safety Glass For Storefront

May 24, 2022

2 Tips For Maintaining Glass Shower Doors

May 20, 2022

An Overview of Safety Glass And Its Applications

May 11, 2022

3 Reasons To Choose Water Jet Cutting Service

April 22, 2022

3 Applications Of Tempered Glass Panels

April 19, 2022

Why Choose Architectural Glass from All Team Glass & Mirror

April 07, 2022

3 Types Of Safety Glass

March 25, 2022

The Importance Of Architectural Glass

March 17, 2022

3 Tips To Choose The Right Shower Enclosure

March 11, 2022

3 Reasons Glass Shower Doors Are Better Than Shower Curtains

March 09, 2022

3 Useful Tips For Home Renovation On A Budget

February 28, 2022

3 Remodelling Ideas For A Small Bathroom

February 24, 2022

3 Reasons To Choose A Sliding Door With Tempered Glass Panels

February 23, 2022

Maintenance Tips For Architectural Glass

February 08, 2022

3 Benefits Of Custom Glass Shower Doors

January 31, 2022

A stylish and sleek bathroom is an extension of a well-planned home. Interior designers and homeowners pay attention to the design of the bathroom to ensure the decor of the house does not feel incomplete. In today's time, there are many additions you can make to the bathroom to make it stylish and better in terms of utility.

Glass shower doors are an excellent addition for those looking to spruce up the bathrooms at their home. They are a perfect replacement for shower curtains and are aesthetically pleasing. However, if you are worried about shower doors not blending in with the rest of your bathroom setting, you can go for custom glass shower doors.

This blog lists the benefits of going for custom glass shower doors.

Design of your choice

One of the significant benefits of going for customized shower doors is that you can pick the design of your choice. Skilled glass fabricators can help design the glass door of your preference, irrespective of its complexity. In addition, a simple internet search can give you inspiration for glass shower doors if you do not have a design of your own.

Thickness

Each bathroom is different than the other in respect of the available space. Therefore, it is imperative to understand that the thickness of the glass shower door is determined based on the available space. Glass fabricators can make customized glass doors of varying size that does not take more space than needed.

Durability

Custom glass shower doors are way more durable than shower curtains. Most glass doors are made using tempered glass known for its strength. Once you invest in getting a custom glass shower door, you can be assured of its durability as it demands minimal maintenance.

You can rely on All Team Glass & Mirror for the best custom glass shower doors. We are a dependable name in the glass fabrication industry. Get in touch with us today to learn about everything we can do for you.

An Overview Of Architectural Glass

January 28, 2022

Everything You Need To Know About Custom Etched Glass

January 14, 2022

Reasons To Choose Glass Shower Doors

January 07, 2022

Everything You Need To Know About Architectural Glass

December 29, 2021

Applications Of Water Jet Cutting Services

December 20, 2021

How Are Tempered Glass Panels Made?

December 10, 2021

Benefits Of Working With A Trusted Glass Fabrication Company

December 02, 2021

5 Undeniable Benefits Of Installing A Glass Shower Door

November 30, 2021

3 Reasons To Choose Tempered Glass Windows

November 24, 2021

3 Undeniable Benefits of Water Jet Cutting Services

November 04, 2021

2 Important Functions of Safety Glass

October 28, 2021

The Benefits of Tempered Glass

October 19, 2021

4 Key Factors to Consider Before Purchasing Architectural Glass

October 12, 2021

5 Basic Steps of Glass Fabrication

October 04, 2021

4 Advantages Of Using Glass Made With Decorative Sandblasting

September 27, 2021

4 Factors To Consider When Choosing Water Jet Cutting Services

September 21, 2021

3 Major Types of Safety Glass And Their Applications

September 10, 2021

Two Common Methods Of Manufacturing Custom Etched Glass

September 03, 2021

Glass Shower Door Ideas for Small Bathrooms

August 25, 2021

5 Uses for Tempered Safety Glass

August 19, 2021

Why Choose Tempered Glass Panels?

August 13, 2021

Top 3 Considerations for Custom Glass Shower Doors

August 05, 2021

How To Choose Between Shower Curtains and Glass Shower Doors

July 26, 2021

Everything You Need to Know About Decorative Sandblasting

July 19, 2021

3 Inspiring Buildings for Architectural Glass Design Ideas

July 14, 2021

5 Uses of Decorative Sandblasted Glass

July 09, 2021

Clarifying the Most Common Myths about Water Jet Cutting

June 24, 2021

What Makes Tempered Glass Panels Highly Credible?

June 21, 2021

Advantages of Architectural Glass

June 09, 2021

Design Tips for Custom Glass Shower Doors

June 02, 2021

Advantages of using Tempered Glass Panels

May 26, 2021

5 Misconceptions about Custom Glass Shower Doors

May 19, 2021

The Uses of Tempered Safety Glass

May 12, 2021

Different Types of Architectural Glass

May 05, 2021

How to Design Custom Glass Shower Doors?

April 27, 2021

4 Reasons to Choose Tempered Glass Panels

April 20, 2021

4 Uses of Decorative Sandblasting

April 13, 2021

4 Frequently-Asked Questions about Safety Glass

April 06, 2021

Choosing The Best Custom Glass Shower Doors Style

March 23, 2021

Architectural Glass That Produces Amazing Creations

March 16, 2021

Top 4 Reasons Fabricators Outsource Water Jet Cutting Services

March 09, 2021

The Preferred Applications of Tempered Glass Panels

March 02, 2021

Among the different kinds of safety glass, tempered glass panels have been the primary choice for construction and manufacturing projects due to its durability and high resistance to heat and corrosion. Better yet, they do not pose a threat for potential danger or injury once they break as they won’t have sharp edges. Hence, they are used for various applications and you can see them almost everywhere.

There are plenty of popular applications when it comes to tempered glass.

A common application is in the construction industry where the primary use of tempered glass panels is to guarantee the safety of everyone. This is why regulations pertaining to the construction industry specifically identify the use of safety glass in constructing residential and business premises. In houses, tempered glass is preferably used as a frameless glass door or sliding door for great protection. It’s also the preferred material for making exterior windows due to its durability. Virtually all glass facade homes use this type of glass, ensuring optimum safety.

Another popular application of tempered glass panels is for automotive windows. The introduction of this material to this industry has been associated with saving lives. Due to its special property of breaking into small, non-lethal fragments, the panels are widely used as vehicle windows, especially on the rear and side. Their use has been highly attributed to fewer traffic accidents and reduced health hazards of broken glass shards.

In addition to its great strength, tempered glass is also scratch-free, making them a perfect material for computer and laptop monitor screens. Though it’s not very likely that you will break the monitor of your computer, you may encounter it with your smartphone. Thus, many smartphone manufacturers are using tempered glass for a durable and scratch-free screen. This same principle applies to the use of this glass material in making home appliances such as the case with ovens in which glass is largely used.

If you’re looking for a tempered glass manufacturer, All Team Glass produces the finest quality of glass products to meet your business’s needs. Contact us today to learn about our unbeatable quality!

4 Reasons Why You Should Choose Custom Glass Shower Doors

February 22, 2021

Whether you're renovating for property resale or simply redecorating to customise your house to your liking, upgrading your bathroom with custom glass shower doors is likely to have crossed your mind. If you choose to go ahead with this idea, you will not only be adding to your bathroom’s elegance but also to its functionality.

If you’re still on the fence, here are four great benefits that glass shower doors offer.

Quality Results With Affordable Prices

Custom glass shower doors aren't too expensive as some homemaking and renovating shows make them be. For example, All Team Glass offers customised glass shower doors inexpensively. However, cheaper than the market price doesn't mean you compromise on the quality of glass and its fittings. You will still receive quality products from highly dependable manufacturers.

Impressive Flow of Light

The flow of light is essential for any bathroom. White light - the recommended and typical lighting form - reveals plenty of your bathroom's details. Having multiple light sources makes visibility constant. However, with a smooth light flow, you can get great lighting without disrupting the relaxed vibe, which is easily achievable with glass shower doors.

Visually Larger Bathroom Space

To make small rooms appear bigger, you can use mirrors. Glass doors in the shower can help you achieve the same result with your bathroom. Typical, non-transparent shower doors and shower curtains can limit your room visibility. Custom shower doors that are transparent help create a larger-than-life bathroom setting.

Easy to Clean and Maintain

With fewer tiles to worry about thanks to your glass shower doors which are like transparent glass bathroom walls, you'll have less mould and grime. Glass requires stain cleaning similar to dining glassware, which is easier to maintain than having to get rid of mould and dirt.

Get the Best Shower Doors

If you are yet to find a reliable supplier of custom glass shower doors, you can always count on us at All Team Glass to help you with all your needs. Contact us today to learn more about everything that we can achieve together.

Two Types of Safety Glass used in Automobiles

February 16, 2021

5 Industries with High Demand for Tempered Glass in Toronto

February 08, 2021

The demand for tempered glass in Toronto is higher than ever. The city is a melting pot of many industrial businesses that use tempered glass as one of their main manufacturing materials.

Although a very common material in the market today, many consumers might still be surprised by the following five industries that often use tempered glass.

Retail and Displays

Especially common in shopping malls and storefronts, tempered glass is used primarily due to its protective qualities. Tougher than annealed glass, tempered glass is able to withstand more physical impact which means retail displays and storefront windows are more secure. If the tempered glass was to break, it shattered into tiny granules rather than breaking into large shards of glass. This is why the retail industry uses tempered glass in Toronto.

Vehicles

Another common industry that uses tempered glass is the auto industry. A car uses two types of glass for its windows. In the front and back windshields, reinforced with a layer of plastic, laminated glass is used to prevent shattering. The side windows use tempered glass so, in the case of emergencies, they can be shattered so the passengers can leave the vehicle.

Kitchen Appliances

If you go to your kitchen right now, you may discover your electric cooktop and oven doors are fitted with tempered glass. Refrigerators will often have tempered glass shelves to withstand storage weight.

Smartphones and Computers

The screen on smartphones is not made of tempered glass. However, there are businesses that create screen protectors made of thin sheets of tempered glass. Desktop computer cases may also use tempered glass as a side panel allowing the interior hardware to be visible.

Athletic Facilities

Modern athletic facilities and community centers are now commonly designed with tempered glass walls and railings. Mainly for aesthetic reasons, tempered glass is still able to function just as well as traditional materials.

Looking to use tempered glass in Toronto? You can always count on us at All Team Glass. With decades of experience providing the highest-quality glass products and fabrication services, we can surely meet your expectations. Contact us today to learn more.

The Power of Water Jet Cutting

February 01, 2021

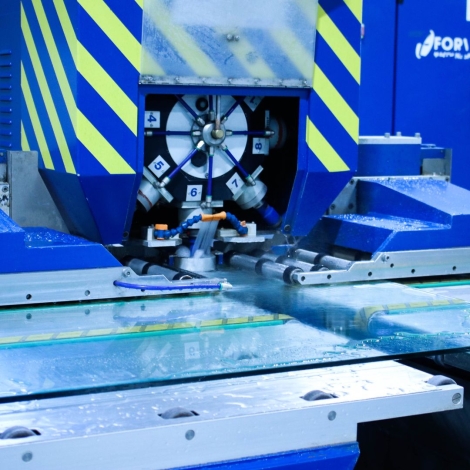

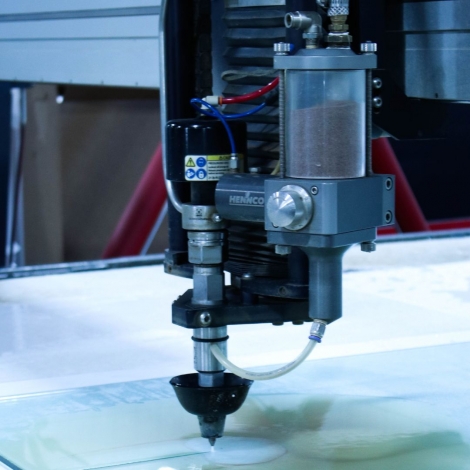

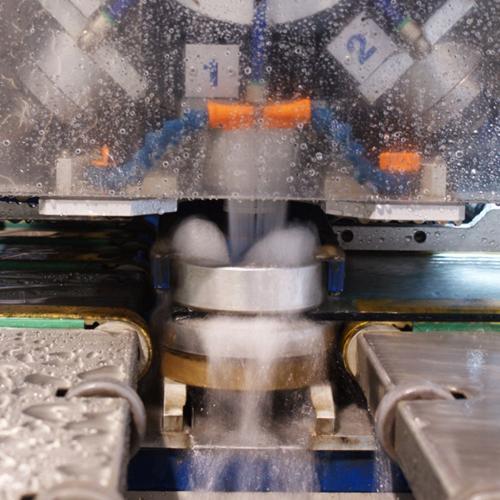

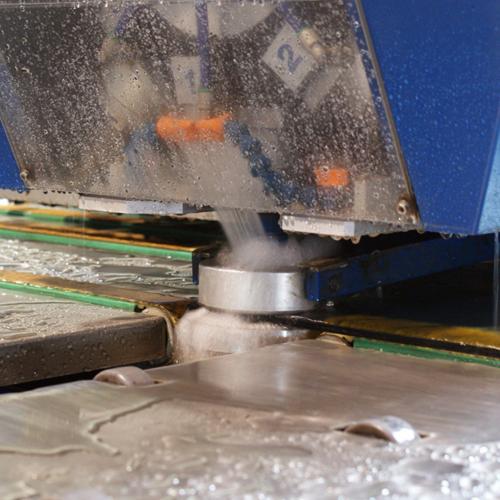

In material processing and other industrial manufacturing, water jet cutting is a relatively new process. Instead of using traditional saw blades, water jets are infused with abrasive granules, continuously streaming out of a nozzle at extremely high pressures, enabling the water to deliver the granules at high speeds with precision. Water jet cutting services have been provided for customers as a way to increase efficiency as well as maintain high-quality cutting as well as a reduced impact on the environment.

Depending on the specific service you need, there are two kinds of water jet technology.

The technology works following a simple cutting principle and process. First, a highly pressurized pump is used to generate a stream of water with extremely high pressures ranging up to tens of thousands of psi, up to 94,000. You can think of this pressure level as more than 90 thousand times more than a single fire hose containing a pressure of over a thousand psi. The next step of the water jet cutting service is converting the high pressure into velocity. This is done by using a tiny jewel orifice that creates a very thin stream of water, as small and thin as a human hair that can cut through most materials.

In addition, in order to further increase the cutting power of waterjet, an abrasive is also used, such as garnet or any other abrasive, that is being pulled into the water stream. As both these media exit the cutting head of the machine, they do at about 4 times the speed of sound which makes them steel more than 1 foot thick. If the material you have to cut is rather soft, then pure water jet cutting service might be enough. Conversely, for hard materials such as stone, composite, and metal, an abrasive waterjet is a better option.

If you are looking for a high-quality cutting service for glass, contact us today at All Team Glass to learn more.

Decorative Sandblasting: Achieving the Design You Uniquely Want

January 27, 2021

Sandblasting is commonly associated with the process of preparing industrial products for finishing and coating purposes.

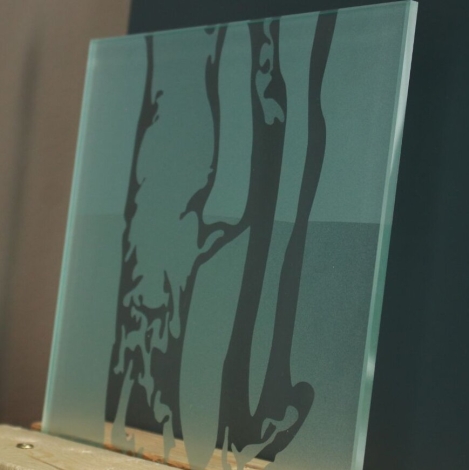

Decorative sandblasting involves subjecting a glass sheet to the abrasive action of sand that is projected by a jet of compressed air. With the impact of the blasting, the transparent and smooth surface of the glass sheet turns rough and opaque. The process can also be done only in specific parts of the surface of the sheet, creating decorative results of great visual effects.

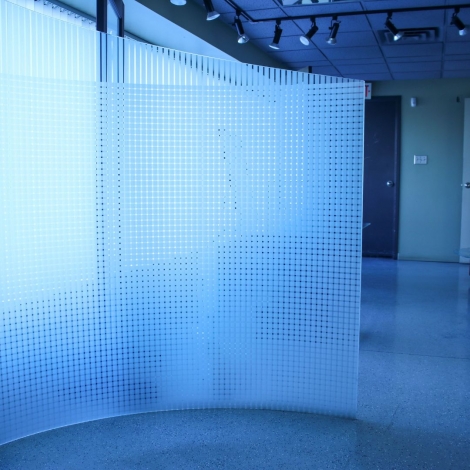

Sandblasted glass, while losing their transparency, can still let the light pass through them. This makes them very helpful in contemporary interior design applications to create an extremely unique and attractive design element. In fact, decorative sandblasting is the most effective way you can give your glass or mirror panels an elegant look. Moreover, designs for your sandblasted glass also vary either with a frosted background or the negative effect, or frosted pattern or the positive pattern. The design is produced with the help of computer design software to give you the best possible results.

It is also possible to hand cut the design to achieve traditional authenticity as multi-level decorative sandblasting can add a beautiful 3D appeal to your glass. The process can also be done on other materials like metals and wood. In terms of other alternatives, a film made from vinyl can also be applied to the glass panels that resemble the design you want to achieve. However, the results can’t match that of the sandblasting with all the details in high accuracy and depth.

The texture that sandblasted decorative glass offers is also unmatched. You can achieve any feeling you want to give to space where you will have the decorative item be installed. Ultimately, you can have that decorative piece stay for as long as you want and it is durable and can last a lifetime.

If you’re looking to add a unique and decorative touch to your glass, contact us at All Team Glass to learn about what our team of experts can do for you!

Highly Versatile Glass For Modern Buildings

January 20, 2021

The performance of laminated safety glass in any structural application largely depends on geometric properties like its composition, aspect ratio, and slenderness. Its structural behaviour is further enhanced with the application of heat strengthening and the tempering to its components. Moreover, the incorporation of high performance coatings, as well as solar control features, make the composite material ideal to use in energy-efficient buildings. This type of glass is perfect for uses in places with warm climates. And finally, there is a wide range of different glass types to choose from, providing various design palettes.

Apart from its safety features, the versatility of laminated safety glass has been widely recognized.

It can be used even in applications where strength is required and can still be provided with either toughened or strengthened components. It can be manufactured for almost all applications to offer protection against ultraviolet rays, solar control, impact, as well as against theft and burglary. Additionally, this glass can be combined with insulating glass and is also applicable for structural glazing. It is indeed a highly versatile material which offers latent integrity and strength.

With the development of advanced computing facilities, the stress analysis of laminated safety glass is subjected to lateral loading becomes easily accessible to engineers. This results in the elimination of the need for the correction pressure factors which are necessary for normal annealed glass design charts. It also leads to the possibility of correct modeling of the effects of the pvb interlayer even at elevated temperatures.

This glass provides solutions to many needs for glass when it comes to meeting design and application requirements. It comes in different composition and thicknesses, offering a great solution to a wide array of uses in modern buildings. If you’re interested in outfitting a building, or component of your home, All Team Glass has an experienced team that provides safety and dedication. Call us today to learn about our range of tempered glass products!

3 Evolving Markets that Depend on Custom Etched Glass Services

January 13, 2021

You'll often see custom etched glass products sold when companies are looking to introduce branded material. There’s lots of instances when etched glass products appear in our lives, for example engraving the names of award winners on trophies that use all kinds of materials, such as stones or metal hybrids for hobbies, sports and even award shows. Glass etching is a service that's considerably necessary for many businesses and markets. However, these three are the most common uses of this customization practice.

Dining and Hospitality

For restaurants that want their signature brand appeal, they can use custom etched glass services to create unique glassware. Furthermore, hotels and other hospitality establishments that impart souvenirs can use glass etching to imprint designs on functional glassware that customers can purchase. Glassware is an intimate part of enriching the dining and hospitality industry, which makes them a primary market for glass etching.

Graphic Art and Design

Designers can create exceptional logos and designs for individuals, organizations, and companies that commission their artistic capabilities. However, artists and studios might have limited resources to finance custom etched glass machines and equipment. Dependable glass etchers, such as All Team Glass, have all the equipment they need to provide the high-quality results their clients expect. In doing so, graphic artists and designers always have a glass etching company in their back pocket.

Schools and Sports Organisations

Award-giving organizations are a high number of glass etching service customers. Most schools want their trophies and medals to look unique with exceptional glass imprints. Sports organizations with specialized awards need custom glass etching that highlight their team aesthetics, such as their logo and colours.

It's Easy to Find the Best Glass Etching Services Near You

If you have yet to find an exceptional glass etching company to work with, you can count on All Team Glass to provide you with the best services. Contact us today to learn more about our customization and glass services!

What to Look for in Glass Shower Doors

January 06, 2021

Glass shower doors in Toronto are a popular bathroom material for most homeowners because of their functionality and pleasant aesthetic.

When it comes to the look of glass, there are plenty of different textures and patterns you can choose from such as clear glass, cast glass, frosted or acid-etched glass, patterned or coloured glass.

If you often share your bathroom, a privacy glass that is heavily textured or frosted is a perfect choice. Other crucial considerations to make in selecting the right glass shower doors for your Toronto home are glass material type, thickness and protection.

When it comes to improved safety and durability, tempered glass is a more suitable option than the annealed glass option. It has been utilized on shower doors for decades now because it resolves the key issue of personal safety during a shower. It can also be operated as a swinging or sliding door, and even as a wall in a shower enclosure as it does not easily break. Conversely, if you prefer to have an extra safety precaution, laminated glass is a better choice because it’s not likely to cause serious injury in case of accidental glass breakage. Laminated glass shower doors in Toronto may look like normal glass but they are actually made of two sheets bonded to a central layer of clear vinyl. Once it breaks, the fractured pieces remain intact because they still adhere to the vinyl.

In terms of how the glass can be protected from harmful or corrosive elements, it’s very essential to extend the service life of the glass. Glass protection is a great option if you want to reduce maintenance. There are various techniques to treat and protect the sealed surfaces of the glass. However, if you are on a budget, glass shower doors can also be treated with a high-end sealant which is applied after manufacturing. This can protect the glass from most stains and chemical corrosion.

If you’re looking to renovate your bathroom we at All Team Glass have the capability to design and manufacture a full range of glass shower enclosures. Indulge in the space you’re in everyday and contact us today to learn about our variety of styles and services!

Tempered Glass Panels and Why it is Used Today

December 22, 2020

Tempered glass panels are being used more often in residential homes today. Not only does it provide an aesthetic that is common in modern architecture and interior design, it is also the material of choice due to its physical properties.

It is a stronger and more secure option, opening a wider range of applications compared to regular glass.

What are Tempered Glass Panels

Tempered glass is produced by treating annealed glass with heat or chemicals, effectively increasing the compressive surface stress of the glass and therefore becoming stronger and more brittle. Increasing the stress in the glass also allows it to completely shatter into smaller chunks on impact rather than larger shards like regular annealed glass. This is why tempered glass is often used with safety in mind.

Light and Security

Glass is a great material to use in modern homes. It provides your living area with more light exposure through the larger windows often designed in modern homes, reducing the need to turn on the lights when the sun is out. Annealed glass is often replaced with tempered glass to increase the security of a home due to its increased strength and resistance to impact.

Design and Applications

In a minimalistic home, you will often find tempered glass panels used for railings, doors, stairs, and in some furniture and appliances. Bathrooms will often have tempered glass doors replacing curtains, which will be easier to clean. Glass stairs and railings will often be a design option for homeowners as tempered glass is stronger and is able to hold a greater amount of weight than regular glass. Desks, tables, and cabinets can also use tempered glass as part of its structure for increased strength and a minimal aesthetic. Electric stovetops also use tempered glass due to its heat resistance while allowing sufficient heat to transfer through the glass.

As a leader in custom glass fabrication and with over 40 years of experience, All Team Glass produces the finest glass and mirror products that meet every client’s specific needs. Contact us today to learn more about our services.

What Makes A Great Architectural Glass Fabricator?

December 21, 2020

Architectural glass is an essential part of any construction and property work. Top-quality glass delivers exceptional insulation and UV protection. Additionally, they're virtually indestructible because of their tempered nature. You'll want to work with greatly-dependable glass fabricators to get the best results for your projects.

Here is what sets apart a fabrication company from others:

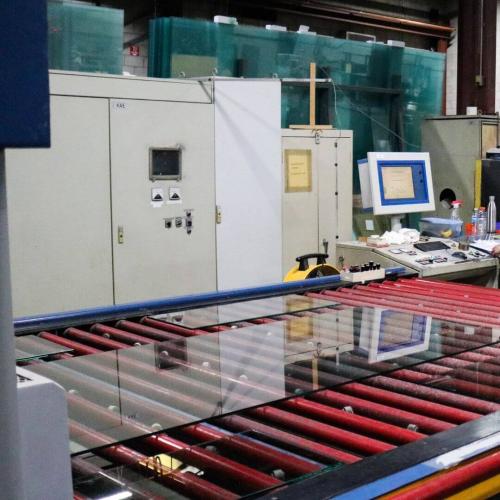

Uses the Latest Technology

Glass is a delicate material, especially before getting tempered. Therefore, it's crucial to work with architectural glass fabricators that use state-of-the-art technology in all their works. New technologies simplify and automate each manufacturing process. In doing so, employees commit zero errors, producing top-grade, durable, and precisely-manufactured glass for construction and other purposes.

Decades of Experience in the Industry

Experience is a challenging yet rewarding teacher. Top-quality architectural glass manufacturers, such as All Team Glass, recognise the value of experience. Dependable glass manufacturers only work with experienced and proven individuals who are highly skilled. By working with them, you can be sure that you'll always have the best results for all your projects.

Provides a Wide Selection of Glass Variations and Reinforcements

Architectural tempered glass is a need for virtually every construction project. However, glass manufacturing is in high demand in various industries. Therefore, a top-tier manufacturer will provide a wide variety of glass suitable for use as mirrors, safety glass, stylish glass etching, bent variations, and more.

Guaranteed Quality and Passion for Providing Their Services

When you work with reliable manufacturers, you can be sure they give their best effort during production. Furthermore, they'll always make it a point to assist you with installations and post-installation checks if you allow them.

You Won't Need to Look Far To Find A Reliable Manufacturer

All Team Glass is the best manufacturer of architectural tempered glass. We work with only the best glass manufacturing professionals and top-quality equipment available in the industry. Contact us today to learn more about everything that we can do for you.

Different Safety Glass and Their Physical Properties

December 15, 2020

Safety glass is much more durable than the regular glass used for lesser applications. It is a thicker material that offers high resistance to physical impact while maintaining a similar transparent aesthetic to that of regular glass.

Common modern-day applications include kitchen appliances, automotive parts, retail fixtures, railings, countertops, solar panels, and much more.

Safety glass can come in a variety of options including tempered glass, laminated glass, and bulletproof glass. Tempered glass is the most widely used of the three options. It is produced by heat-treating annealed glass panels in an oven effectively strengthening the glass. Unlike regular glass, when tempered glass succumbs to physical pressure, the entire panel shatters instead of leaving sharp jagged edges, therefore lowering chances of injury. Due to these physical properties, tempered glass is in high demand for daily applications including passenger vehicle windows, shower doors, tables, and countertops, as well as a component to bulletproof glass.

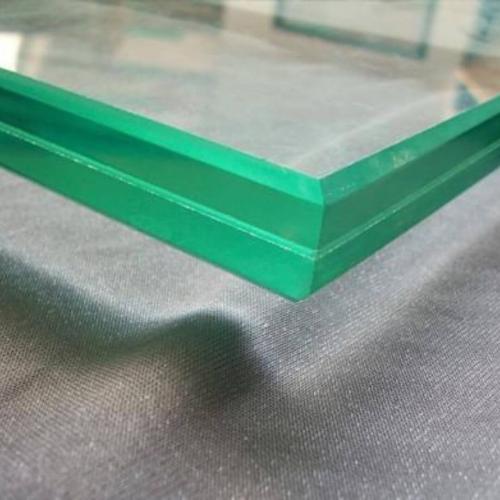

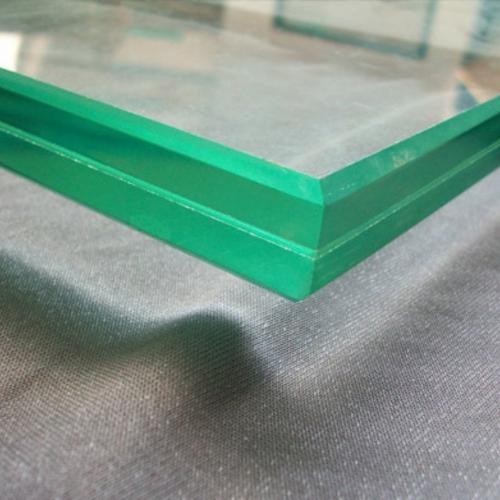

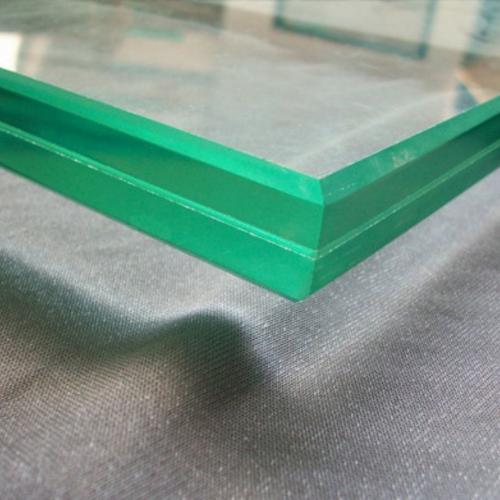

Laminated glass is created by adhering multiple layers of glass together, with a thin vinyl layer in between each slab of glass, offering protective qualities that make it resistant to shattering upon impact. This makes laminated glass the preferred option for car windshields and retail windows and doors, and glass railing panels.

Armored glass, otherwise commonly known as bulletproof glass, is a combination of multiple types of glass. As the name suggests, this glass is the durable option of safety glass offering the most protective qualities. It takes the physical properties of tempered glass to resist highly focused impact, distributing pressure throughout the panel by minimizing shatter points in small regions around the impact. The use of lamination in armored glass will allow for multiple thick layers of glass as well as maintaining the glass barrier without shattering upon heavy impact.

If you are looking for expertise in tempered and laminated glass in Toronto, All Team Glass has been an industry leader in custom glass fabrication since 1975. Contact us today for all your custom glass options.

4 Distinct Advantages of Architectural Glass in Buildings

December 02, 2020

Glass has become a popular and important construction material for many different kinds of buildings. Truthfully, architectural glass has been around for decades. It continues to dominate with its exceptional aesthetic and top-notch performance thanks to high-quality manufacturing practices. Today, modern buildings all have impressive glass facades as part of their most recognizable feature.

Here are four distinct advantages of using glass in structures:

Adds Beauty to Otherwise Mundane Buildings

Brutalist architecture is beautiful, but buildings with architectural glass make for excellent contrasts. Beautifully-shaped architectural window and door glass give buildings a distinct characteristic, making them memorable and timeless. Glass can become a powerful centerpiece in any property.

Natural Light That Lowers Bills and Improves Mood

Sunlight nourishes human perception and moods, aside from providing Vitamin D. With the right coatings, architectural glass can also filter out UV rays while letting natural sunlight inside properties, achieving beautiful lighting without extra costs. By using low-output lights only during nighttime, a property can save a lot in electricity bills.

Completely Recyclable and Non-Degrading

Glass is a 100% recyclable material that does not degrade. It does not decompose or have altered or diminished capacities or characteristics once melted and re-sculpted. In doing so, you can rest assured that your building, if it uses glass, has utilized more sustainable materials.

Efficient Insulator

Window and door glass have double and triple-glazed variations, disallowing outside temperatures from influencing the inside temperature of the property. As they are able to achieve excellent insulation, glass windows and doors have now become a staple in architecture.

Get the Best Glass From Renowned Manufacturers

With long-term experience, state-of-the-art fabrication technology, and dependable employees, All Team Glass is confident in handling all your glass needs. We can create mirrors, safety glass, and architectural pieces for any property. Contact us today to learn more about our products and services.

Top 3 Criteria for Choosing Glass Shower Doors

November 23, 2020

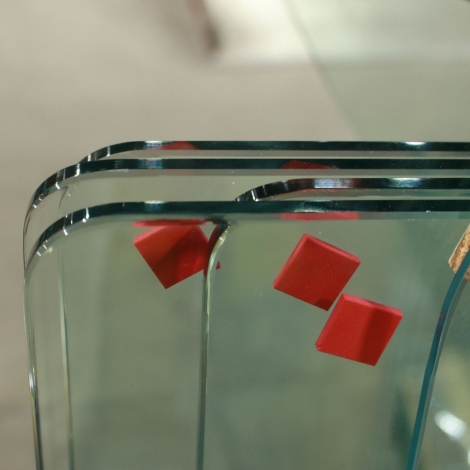

Because of their functionality and aesthetics, glass shower doors in Toronto have become popular for many homeowners. In terms of appearance, they come in different textures and looks such as coloured, patterned, clear, frosted, acid-etched, or cast glass. If your bathroom is shared, a privacy glass that is heavily textured or frosted would be a perfect option for you. Other essential factors to take into account when choosing glass shower doors include glass material type, thickness, and protection. Each of these criteria will be discussed below.

Glass type: tempered or laminated?

If you prefer safety and durability, tempered glass is a good choice compared to annealed glass. This glass material is the one that is most commonly used for glass shower doors in Toronto. These shower doors can either be sliding or swinging. Either way, they don’t easily break. If you need to have extra safety precautions, a laminated shower glass door is perfect as it can minimize the risk of serious injury in case of accidents. Due to its exceptional strength, the broken pieces remain intact once it fractures.

Material thickness: how thick the glass will be?

Glass shower doors in Toronto are made with a varying thickness which is somewhat dictated by whether it’s a framed, semi-frameless, or frameless unit. The thickest of them is perfect for the frameless style glass whereas the thinner glass is great to be used in framed units for more structural support that safeguards vulnerable corners of the tempered glass.

Protection: how will the glass be protected?

Protecting the glass from harmful or corrosive chemicals is crucial to prolonging its life. Glass protection is also helpful in order to reduce maintenance. Ion-beam technology is one of the techniques to treat and permanently protect the sealed surface of the glass. If you have a restrictive budget, glass shower doors in Toronto can also be treated with a high-end sealant that is applied after manufacturing. It can protect the glass from stains and corrosion.

For all your glass needs, be sure to contact us at All Team Glass!

4 Critical Uses of Tempered Glass Panels

November 18, 2020

Basic glass products can be brittle and weak. When they break, they typically shatter into small, sharp pieces that are dangerous. This is why a different type of glass needed to be developed for applications that require more strength and safety. Tempered glass panels have reinforced, hardened materials that take typical brittle glass to the next level.

Here are four applications of tempered glass panels:

Heat Resistance

Manufacturers of excellent drinking glasses use a typical glass that cannot resist high levels of heat. However, tempered glass panels, which oven, stove, and kitchen appliance manufacturers use in their appliances extensively, can resist higher heat levels. In doing so, they become crucial components of not just residential appliances, but also industrial-level kitchen equipment.

Vehicle Protection as Windows

Almost all vehicles nowadays use tempered glass panels as windows. Reinforced vehicle windows can withstand a hammer's impact. Windshields have double the density of typical tempered glass for added driver and passenger protection. Furthermore, if the glass is impacted to hard that it shatters, its pieces will stay together rather than fall into sharp pieces.

Retail Store Displays

Countertops, display corners, and shop fronts use tempered glass for optimal protection. In doing so, shops can display and advertise their goods without fear of somebody attempting to break in quickly. Furthermore, top-quality tempered glass, such as those that All Team Glass manufactures, provides complete-sealing insulation.

Laptops and Smartphones

Smartphones, laptops, and other LCD devices nowadays have reinforced glass, which can withstand significant impact. Truthfully, they might add to device production cost, but their benefits are undeniably worth the added price.

If you have yet to find a dependable glass manufacturer, you can always count on All Team Glass to deliver what you need. With decades of collective experience in the industry and top-grade glass manufacturing equipment and facilities, we're confident that we can deliver everything that you need. Contact us today to learn more about our products and services!

Different Options for Architectural Glass

November 10, 2020

From trendy and clean to ornate and complex, architectural glass can come in many different styles and types. In the past, the use of glass was limited to practical applications in terms of windows. However, as architecture continued to advance, glass has been put to more creative uses and is mixed with other materials to offer solutions that were not possible before. Today, this type of glass is known as architectural glass. It can be used to make floors, walls, and ceilings.

In terms of options and surfaces, there are various types of glass available in the market:

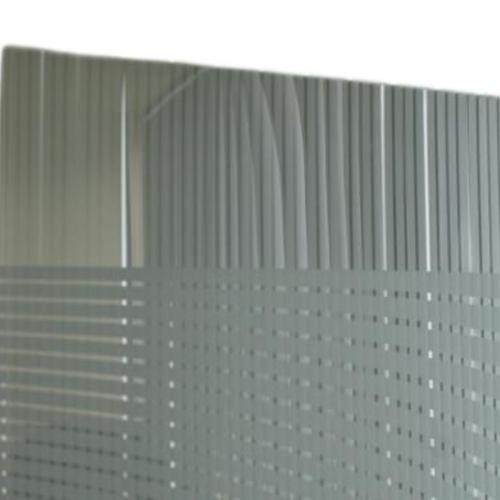

One of the features you can add to architectural glass is etching. You can create custom designs on your glass which can be seen from both sides. Etched glass is typically used for doors, as the ornate design stands out more.

One more important factor to consider when planning to use architectural glass is to have the right kind of edging for the product. The edges of the glass have to be polished which means that their corners will be processed. This process will remove any imperfections on the glass edge, resulting in smooth beveling that can be made into varying styles.

Also, you can have either rounded edges or sharp corners. Whatever your choice is, the final look of your glass product will be largely determined by the length of the cut edge or its thickness. In case you want to have your glass laminated, there are also different options when it comes the types of lamination you can use. There are strength-enhancing laminations as well as ones that are meant for specific weather conditions. It’s critical to have any drills or cuts be done prior to the lamination. Otherwise, it won’t be possible to do so afterwards.

Whatever your specifications are, you can bet that the fabrication team at All Team Glass can get it done. Just get in touch with us to learn more about your options!

3 Undeniable Advantages of Water Jet Cutting

November 04, 2020

There are a wide variety of uses for water in industrial settings. For instance, a water jet cutting service can efficiently cut shapes and parts as precisely as mechanical and laser cutters. Water jet cutters introduce a powerful approach to traditional pressurised water applications using a pump capable of delivering 4,000 bar water pressure.

As such, it is popularly use in many manufacturing plants, specifically for glass cutters and fabricators.

Water Can Cut Through Almost Every Material

4,000 bar water pressure is capable of cutting through almost every material. Aerospace and vehicle manufacturers utilize water jet cutting services to cut and shape many materials. Jet cutters can process steels, alloys, titanium, and other essential metals for frame and parts manufacturing. It may sound unbelievable to use water to cut such sturdy objects, but the results speak for themselves.

Precision, Uncontaminated Cutting

Water jet cutting provides regular, detail-oriented nozzle maintenance. This component makes it possible to cut accurately and allow the passage of cutting abrasives, which refine and cut materials to basic shapes and sizes. In doing so, nozzles of water jet cutters provide precise, uncontaminated, and flawless cutting results.

Highly-Accurate Cutting Tables

Well-maintained cutting tables ensure the full accuracy of all cutting and shaping procedures. Furthermore, their superior locking capabilities guarantee the precise duplication of processes for materials that require identical processing.

Glass Manufacturers Only Use the Best Water Jet Cutting Technologies and Methodologies

Water jet cutting provides the best alternative to traditional and laser cutting services thanks to its cold cutting process. In doing so, it prevents any possible melting, tearing, or deformation on workpieces.

If you are looking for glass fabrication services, it helps to work with reliable, professional water jet cutters for all your needs. We at All Team Glass have long-term, qualified experience to provide you with the best jet cutting services. Contact us today to learn more.

Architectural Glass Through the Ages

November 02, 2020

Whether it is energy efficient, laminated, toughened, clear or tinted, glass is a staple for modern architecture and is never overlooked when designing commercial and residential buildings.

Before it earned its great popularity and accessibility these days, only wealthy people could really afford the lavish look that glass brings to a building. In particular, the earliest form of architectural glass was created for the most significant structures in Italy and was very expensive if used in building homes.

As glass production continued to grow increasingly in the ensuing years, glass doors and windows have remained to be exclusive for the rich to afford. Take for example the particular case in England wherein the more glass windows a home contained the more wealthy the owner was considered. This being the case, it’s quite unthinkable that there was a time before when people were taxed depending on the number of glass windows found in their homes. When this said tax policy was lifted, the price of architectural glass also dropped significantly to almost half the original cost.

With the advent and introduction of automated float glass manufacturing techniques, the addition of glass became widely available at a moderate cost but with the same high quality. This production method was utilized to make flat glass panes, in which molten glass was being poured into a thin bath for it to spread smoothly and flat. What further increased the manufacturing of architectural glass in history was the advancement in steelmaking.

Steel frames became the most commonly used material to support buildings. It meant that the walls could then be relieved of their load-bearing burden and be made entirely of glass, or popularly known as curtain walls. With this advancement, architects along with glaziers were pushing glass to its limits. Though glass material is very delicate, it can be strong and flexible, which makes the possibilities endless when it comes to its design.

If you’re interested in incorporating glass in a functional and beautifully unique way into your next building project, please contact us at All Team Glass to find out how we can make your design vision a reality.

3 Astounding Qualities Any Top Glass Manufacturer Should Possess

October 21, 2020

Whether it's a commercial property glass covering or a home renovation project, finding the best glass manufacturer in your area is important. Reliable manufacturers, like All Team Glass, understand the complete needs of any project. They're not just trying to make a sale of their products and services -- they want to create a long-term relationship with you for all your project needs. Here are three exceptional qualities manufacturers should possess:

Decades of Unparalleled Dedication to Perfection

Any glass manufacturer recognizes its task is somewhere in between making art and developing long-term dependable and durable solutions for its clients. Most of them learn this through experience by applying theoretical knowledge. Therefore, if you work with companies that have vast experience such as All Team Glass, you'll have some of the finest custom glass services you need for all your projects.

Environmentally-Conscious Procedures and Efforts

Experienced and long-standing manufacturers will recognize that their work has environmentally hazardous elements. In turn, they will take initiative to use environmentally-friendly methods. To optimize and minimize their carbon footprint, manufacturers like All Team Glass use recycled glass, which guarantees excellent project results without compromising quality.

Offers a Wide Range of Options for Any Project

Architectural glass manufacturers such as All Team Glass offer glass and When you'mirror products with a wide range of options that work for both interior and exterior applications. With decades of research and experience combined, our teams can produce top-quality products that are affordable and introduce extraordinary results for interior design, architectural exterior cladding, and more.

It's Easy to Find a Reliable Glass Manufacturer Near You

All Team Glass considers every small detail of your project needs, which will provide you the best solutions that will yield your intended results. With more than 30 years of experience, we can cater to your glass design ideas. Contact us today to learn more about what we can do for you!

4 Real Scenarios Where Custom Glass Fabrication Adds More Value

October 15, 2020

Custom glass fabrication sounds expensive, however it doesn’t have to be if you’re going to the right service provider that will fit your needs, like All Team Glass. Modern manufacturers who care about the environment and optimising their budget use recycled glass to bring about exceptional glamour and style to properties.

Here are four scenarios where affordable custom glass can greatly increase value.

Unique Glass Walls for Public Facilities

Local tourism efforts will always need something new and exciting for foreign and local visitors. In cities, the normal public payphone corner or even pedestrian seats for resting can become unique by using custom glass fabrication to introduce an encasement or a glass sculpture for a seat. The possibilities are endless when partnering with experienced glass manufacturers.

An Exterior Centrepiece

Just like how unique glass pieces can work for public facilities, exterior centrepieces can be transformative for commercial and industrial properties. If you need a powerful glass sculpture or an eye-catching piece that will greatly impress your clients, working with us at All Team Glass will make it easy to find an exterior centerpiece that is exciting and beautiful.

Customised Shower Walls and Doors

Home interiors can greatly benefit from custom shower doors. The additional relaxing glamour, thanks to the added stimulation of visuals, creates a radical shift in property aesthetics and overall property value. Most home remodelers use custom glass fabrication services to increase value in flipped properties.

Any Architecturally Radical Idea

If you have an outrageous idea for glass, we at All Team Glass are willing to hear about and manufacture it for you. With decades of experience handling some of the most difficult and intricate architectural glass projects, we guarantee exceptional results for all your needs. Contact us today at All Team Glass to learn more about everything we can do for you.

Why you should choose water jet cutting services

October 08, 2020

A water jet cutter or a waterjet is an industrial tool that is able to cut through a wide variety of materials using an extremely high-pressure jet of water. Water jet cutting services are used to cut various materials that would otherwise have a difficultly with other procedures. Sometimes, the water has an abrasive added to it to help cutting hard materials like metal or granite.

The process is generally used to fabricate various parts of machines, especially when the materials being cut are sensitive to heat or high temperatures generated by other cutting methods. Waterjet cutting is used in various industries such as mining and aerospace for cutting, shaping and reaming.

When you opt for a water jet cutting service, here is what takes place.

Water is passed through a high-pressure pump and into a waterjet. The waterjet has a nozzle built to withstand the force and pressure exerted by the stream of water. This jet of water can measure up to Mach 3 or around 2,500 ft/s (760 m/s) which is approximately the same speed at which certain fighter jet planes fly. If the task requires an abrasive waterjet, then the process is slightly different. Just before the water escapes the nozzle, abrasive elements such as garnet and aluminium oxide are fed into the nozzle through an abrasive inlet. This abrasive then mixes with the water to create an even more effective cutting tool.

Benefits of using a water jet cutting service include an accuracy of down to 0.005 inches and repeatability down to 0.001 inches. Using a waterjet also reduces the amount of scrap metal left over after cutting due to its relatively low kerf. Since there is no heat generated when using a waterjet, it is the process of choice when dealing with heat-sensitive materials. This allows for highly accurate, sharp and waste-less cutting.

Amazing Structures Made of Glass

September 23, 2020

It is undeniable that one of the most remarkable building materials in the world is glass. With the amazing benefits it gives in terms of both support and aesthetics, it is unsurprising that it is utilized in building homes, offices, and any other kind of structure. Architectural glass, in particular, is of great interest to most interior designers and architects around the world. This is primarily because the material provides perfect access to natural light as well as plenty of customization options, while still being strong and stable.

More importantly, it offers the ability to blend interiors with exteriors and transform a structure into a thing of elegant and astonishing beauty.

Some of the breathtaking projects where architectural glass was excellently used include the following:

The National Centre for Performing Arts in China

More popularly known as The Giant Egg, this amazing work of art incorporates intricate designs on glass with perfect symmetry. This massive structure is built to be iconic, which was a feat indeed achieved. A man-made lake surrounds the building, making the architectural glass and titanium stand out even more, creating a great vision that is not only beautiful but also out of this world.

Prada Store in Japan

Jam-packed with fashionable structural elements, the Aoyama district in Tokyo, Japan becomes more striking both to locals and tourists because of one of its most astonishing buildings - the Prada Store. The store sports an eye-catching architectural glass facade with wonderful rhombus-shaped doors alongside elegant lighting. The whole building perfectly reflects the company’s glamorous brand.

The National Stadium in Taiwan

Perhaps its unique dragon-shaped glass design is the building’s most distinctive element. But more than that, the stadium’s greatest wonder is its remarkable use of renewable energy through more than eight thousand solar panels that cover almost the entire roof of the structure. It allows the building to supply its own energy use, achieving more than 100% of its required consumption, with the surplus safely stored.

As you can see, architectural glass presents incredible aesthetic opportunities, both modern and classic. For all you glass fabrication needs, make sure to get in touch with All Team Glass!

The 4 Popular Applications of Tempered Glass

September 21, 2020

When it comes to safety applications, tempered glass is the best way to go. It can be used in various ways in both industrial and commercial spaces. Tempered glass panels are perfect to use as replacement glass, shower enclosures, and so on. They have been the top choice of many users due to their durability and great resistance to heat. Moreover, they also do not pose a potential danger for injury when they break because they don’t have sharp edges. Hence, they are used for many applications and you can see them almost everywhere.

Here are the top three popular applications of tempered glass panels:

In the construction industry

The ultimate goal of using tempered glass is to ensure the safety. This is why regulations that pertain to the construction industry especially identify the use of safety glass in building both residential and business properties. In houses, tempered glass panels are commonly used as a frameless glass doors or sliding door for maximum protection. They are also the preferred material for creating exterior windows due to the material’s durability. Virtually all glass facade homes use this glass, ensuring safety.

In the automotive industry

The frequent application of tempered glass for use in the automotive industry is largely attributed to saving lives. Because of the glass’s unique ability to shatter into small, non-lethal fragments, it is widely used as vehicle windshields. Its use has been also associated with fewer traffic incidents and reduced health hazards of broken glass shards.

In the computer industry

Apart from their great strength, tempered glass panels are also scratch-free, making them a perfect material for computer and laptop monitor screens. While it’s not as likely that you will break the monitor of your laptop or desktop, you may encounter this problem with your mobile phone. As such, many smartphone manufacturers are utilizing tempered glass to make for a durable and scratch-free screen.

4 Compelling Benefits Of Using Tempered Glass Panels In Your Property Projects

September 11, 2020

For many people, tempered glass panels are only thought of as the protective glass layer for smartphones. However, tempered glass can do so much more than protect electronics. It is commonly used in property projects as architectural glass for balcony and shower doors, swimming pools, and fencing.

Here are four great benefits to using tempered glass in property projects:

Stronger Than Normal Glass

If annealed glass were to be damaged, even a small crack can cause an entire panel to turn brittle once vibrations start propagating the crack. However, due to its surface compression, tempered glass panels will contract and contain the cracked areas. In turn, it is genuinely physically stronger than annealed glass with a compressive stress of 10,000psi.

Explosion Proof

The exceptional surface pressure on tempered glass panels can handle and deflect blunt objects travelling at high velocities. As such, it's powerful enough to withstand severe damage and may be able to shield any people or objects on the other side of the glass. Furthermore, if it should break, tempered panels break down into blunt pieces, which makes them less dangerous for passengers during an accident.

Exceptional Thermal Resistance

Tempered glass is perfect for vehicle use because of its highly-exceptional thermal resistance. It is commonly implemented in window panels as well. Glass panels for vehicle and property windows go through a repeated cycle of heating and cooling. Such a process will damage standard annealed glass panels. However, tempered glass' surface compression keeps it intact despite the changing temperatures.

If you need exceptional glass panels for your projects, you can always count on us at All Team Glass to provide you with the best-tempered panels for vehicles or properties. With decades of glass manufacturing and fabrication experience, you can rest assured that everything we do meets or exceeds industry standards. Contact us today to learn more about our services and facility!

The Convenience and Versatility of Architectural Glass

September 09, 2020

Glass is everywhere in buildings, whether residential or commercial, small homes or large malls. With that said, not all glass types are the same. Glass that is used in windows is not the same as glass that is used in constructing enclosures. The latter is known as architectural glass, and is typically simply defined as glass that is used as a building material. It is most commonly used in building envelopes as well as internal partitions, with safety variations that are reinforced or laminated.

A Subtle but Additive Design

Architectural glass is subtle. Thanks to its transparent, colourless, and background-oriented qualities, it has a subtle presence contributing to your overall interior design. Simplicity is the name of the game here. A simple partition can do wonders to open up a room and present a modern, sophisticated image. New-age interior design uses glass extensively as a replacement for woodwork and concrete. Durable, reinforced architectural glass makes it possible to use it as furniture, seats, and walls. For most restaurants, it's the perfect wall-style partition that does not occupy visual space but creates excellent rhythm and organization.

Protection and Insulation

Safety-oriented and toughened glass can serve as a protective yet uncluttered window for your property. In many cases, life-sized ceiling-to-floor windows use reinforced glass to act as a support structure and protective barrier that does not hinder the viewer's line of sight. Furthermore, their laminated and seamless installation contributes to the property's overall insulation.

A Wide Variety of Glass to Choose From

Architectural-oriented glasses have numerous versions that guarantee extensive physical protection and provide a substantial aesthetic boost. Reliable glass manufacturers, such as All Team Glass, only create the best decorative and protective glasses available.

With over 45 years of collective experience and service providing top-tier glass products, we at All Team Glass have full confidence to deliver the glass you need. Contact us today to learn more.

Why Safety Glass Is Very Strong and Durable

August 26, 2020

As a better alternative to standard glass which is commonly used for creating house windows and doors, safety glass is designed to reduce risks of injury during damage, thus offering much more security. It is commonly used in applications that demand increased protection or uses that are prone to physical harm. It was first developed in the early 20th century through celluloid polymers and adhesives. Since its introduction, it has become widespread in residential, commercial, and industrial applications.

What are the different types of glass available?

The common forms of modern safety glass include tempered, laminated, and armed glass. Of these three types, the tempered glass, also known as toughened glass is the most widely used. It is a heat-treated glass material that is specially made for high strength and safe shattering. This kind of glass does not break into sharp edges. Rather, they shatter into small pebble-like pieces. The glass is processed through a tempering process that heats the glass to a very high temperature of between 1100°F and 1300°F.

Once the heat treating is done, the glass will be cooled down quickly using powerful drafts of cold air. Once it has cooled down, it hardens under the stress exerted onto its structure. The resulting glass is much stronger and is capable of withstanding about five times the amount of force applied to break the untreated glass. The main drawback with safety glass, however, is that it’s quite difficult to manufacture as it should be cut or shaped prior to heat strengthening. Moreover, it is prone to break entirely from impact instead of leaving fragments intact.

Despite these cons, tempered glass is often used as the side and rear windows of automobiles because of its safe shattering qualities and high impact resistance. Likewise, it is also utilized in building doors, shower enclosures, mass transit windows, sliding doors, as well as large home appliances. Other types of this glass are also found in uncommon projects such as bullet-proof shielding and small-scale explosive blast protection.

So, when you need tempered glass in Toronto, All Team Glass is the best place to look. All our products are produced in accordance with Canadian industry standards and tested in a third-party laboratory - this is to ensure you with durable and extra strong glass products for your complete safety.

4 Compelling Benefits Of Using Tempered Glass Panels In Your Property Projects

August 12, 2020

For many people, tempered glass panels are additional protective glass layers for smartphones. Upon application, these exceptional panels that contain the smallest cracks provide the best protection for fragile smartphone touchscreens. However, tempered glass can do so much more than simply protect electronics. You can use it for balcony and shower doors, swimming pools, and public property. Here are four great benefits to using tempered glass.

Stronger than normal glass, annealed glass can have a small crack, which turns an entire panel brittle once vibrations start propagating the crack. However, due to its surface compression, tempered glass panels will contract and contain the cracked areas. In turn, it is genuinely physically stronger than annealed glass with a compressive stress of 10,000psi.

Explosion Proof

The exceptional surface pressure on tempered glass panels can handle and deflect blunt objects travelling at high velocities. In turn, it's powerful enough to withstand something as big as an explosion and can shield anybody on the other side of the glass. Furthermore, if it should break, tempered panels break down into blunt pieces, which makes them less dangerous for passengers during an accident.

Exceptional Thermal Resistance

Tempered glass is perfect for vehicle use because of its highly-exceptional thermal resistance. It sees comprehensive implementation as property window panels too. Glass panels for vehicle and property windows go through a repeated cycle of heating and cooling. In doing so, its contraction and expansion will damage standard annealed glass panels. However, tempered glass' surface compression keeps them intact despite the changing temperature.

A Great Number Of Exceptional Manufacturers

If you need exceptional glass panels for your projects, you can always count on us at All Team Glass to provide you with the best-tempered panels for vehicles or properties.

You won't need to look far to find the best glass manufacturers -- Contact us today to learn more about everything that we can do for you!

4 Ways to Customize Your Glass Shower Doors

July 21, 2020

Nothing says luxury and beauty more than getting your own elegant glass shower doors in Toronto. However, what has been "en vogue" in the last ten years might not be stylish and value-adding this year. If you are looking for ideas about boosting your interior aesthetics with glass shower doors, here are a few ideas that we've seen from home remodelers and other successful projects.

Go Frameless

Aluminum, chrome-plated frames do look great. However, you can find these in virtually every home, making them look dull and typical. Thanks to technology and the advanced manufacturing of elegant glass shower doors in Toronto, homeowners can use frameless glass panels. These doors attach themselves to your wall to achieve an exceptional aesthetic effect, and remain sturdy and structurally sound.

Shower Enclosures

Fiberglass is one of the best investments you can make for modern glass shower doors in Toronto. It is light enough that it can be used to build an entire shower enclosure that stands on your shower floor and attaches to your walls. Frosted and sandblasted variants are often available from high-quality manufacturers of custom shower doors, such as All Team Glass.

Hinged Enclosures

When it comes to style and beauty, hinges are still beautiful -- as long as you use custom hinges designed for your glass shower doors and walls. A chrome or gold-plated hinge will bring out the beauty of white-walled and light-coloured bathrooms, adding pizzazz and grandeur to your bathroom.

Sliding Elegance

Nothing feels more elegant than doors sliding silently, emitting no screeching sounds. Elegantly-sliding glass shower doors can help you achieve specific aesthetics, all while guaranteeing convenience and cleanliness.