How Are Tempered Glass Panels Manufactured?

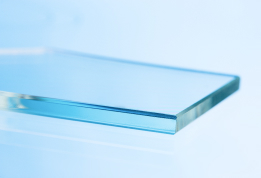

Have you ever wondered how tempered glass panels are made? These sturdy and durable panels have become increasingly popular in recent years, thanks to their ability to withstand extreme temperatures and impacts. From phone screens to car windows, tempered glass has found its way into a variety of applications. If you're curious about the manufacturing process behind these impressive pieces of glass, keep reading!

The Manufacturing Process of Tempered Glass Panels

Are you wondering how is tempered glass manufactured? If yes, read on to learn all about it.

Step 1: Cutting and Grinding – The initial step of tempered glass manufacturing involves cutting the glass into the desired shapes. This is often done with a diamond-tipped cutting saw or laser cutters. After that, the edges are ground to remove any sharpness and smooth them out.

Step 2: Heating – Next, the tempered glass panels are heated in an oven at temperatures ranging from 600-700 degrees Celsius. This process is to soften the material before it is formed into its final shape.

Step 3: Tempering – Once the glass has been heated up, it is placed in a tempering bath which consists of molten metal or nitrogen gas. This helps to strengthen the surface of the panel and make it more durable for use in applications such as windows, shower doors, etc.

Step 4: Cooling – After tempering, the panel is then cooled down quickly by blowing air onto its surface from an air jet nozzle or by immersing it in cold water. Rapid cooling helps to harden and toughen up the glass making it stronger than normal glass panels.

Step 5: Final Inspection – After all these steps have been completed, a final inspection is done to make sure that there are no defects on the tempered glass

Quality Control

Quality control is of utmost importance when manufacturing tempered glass panels. Every piece of glass must be inspected for flaws and imperfections before it is sent through the tempering process. If even a small crack or chip is found, the piece of glass must be discarded to avoid the risk of the panel shattering during tempering.

Once all of the pieces of glass have been inspected and cleared for tempering, they are placed into the furnace. The furnace heats the glass to very high temperatures, before gradually cooling it down. This process strengthens the glass and makes it more resistant to breakage.

After the tempering process is complete, each panel is again inspected for flaws or imperfections. Any panels that do not meet our high standards are rejected and recycled. This ensures that only the highest quality tempered glass is used in our products.

Conclusion

Tempered glass panels are a beneficial and widely used product. Knowing how these panels are manufactured is key to understanding why they are so strong and durable. The process of tempering the glass involves heating it quickly followed by cooling rapidly, which strengthens the molecular bonding of the panel for increased strength and safety. You can rely on us at All Team Glass & Mirror Ltd. for all your tempered glass needs. We are one of the leading glass manufacturers in Ontario. Call us today to learn about everything we can do for you.