The Uses Of Decorative Sandblasting In Glass Fabrication

Decorative sandblasting is a process in which abrasive particles are blasted at high pressure onto a surface to create a decorative effect. This technique on various materials, including glass, metal, and stone.

Sandblasting Is Mainly Used For Two Purposes:

- To create patterns or designs on surfaces

- To remove paint or other finishes

All Team Glass & Mirror Ltd. is a leading name in the glass fabrication industry. Our team of expert fabricators uses sandblasting to offer decorative glass products, of the best quality, to our clients.

Here Is Everything You Need To Know About Our Sandblasting Process

There are a few things to keep in mind when sandblasting for decoration. First, it's essential to use the right type of abrasive material. We use sand as it is proven to be the most effective method for glass fabrication. Second, it is critical to set the correct blast pressure and distance depending on the nature of the project. Too much pressure or less distance between the sandblasting machine and the glass can cause damage.

Here Are The Different Types Of Decorative Sandblasting

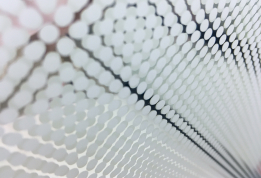

- Surface shading: Surface shading gives a three-dimensional look to the designs. This is because surface shading creates contrast against the transparent glass.

- Surface etching: Surface etching offers a frosted look to the glass, making it hugely popular.

- Carving: You can carve designs on glass using this sandblasting type.

Our skilled fabricators have been in the business for years. The experience of handling diverse glass fabrication projects has helped our employees master sandblasting technique.

Major Applications Of Decorative Sandblasting

- Signages

- Glass trophies

- Special glass projects (decorative)

Get in touch with our team today to learn about the wide range of products and services we offer. With decades of experience, we guarantee nothing but the best to all our clients. We manufacture and supply architectural glass at the best rates.