Water Jet Cutting And The Glass Industry

Water jet cutting is a process that uses high-pressure water to cut through materials. It’s a versatile technology that can be used on a variety of materials, including metal, stone, glass, and plastic. In the glass industry, water jet cutting is primarily used for decorative purposes. It can be used to create patterns and shapes in glass that would otherwise be impossible to achieve with traditional cutting methods. Water jet cutting is a relatively new technology, but it’s already making a big impact in the glass industry. In this blog post, we’ll explore how water jet cutting service is beneficial for the glass industry.

How Does Waterjet Cutting Work?

Waterjet cutting works by using high-pressure water to cut through the material. The water is forced through a small opening at very high pressure, which creates a jet of water that can cut through almost any material. Waterjet cutting service is often hired in the glass industry because professionals can create very intricate designs and shapes that would be difficult to create with other methods.

What Are the Benefits of Using Waterjet Cutting for Glass?

The benefits of hiring waterjet cutting services for glass are:

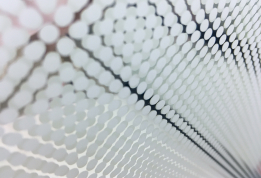

1. It is very precise and can create intricate designs.

2. Waterjet cutting is clean and doesn't produce any harmful fumes or waste.

3. It is fast and efficient, and can be used to cut large pieces of glass quickly.

4. Waterjet cutters are versatile and can be used to cut different thicknesses of glass.

How is waterjet cutting used in the glass industry?

In addition to cutting and shaping glass, the waterjet can also be used for engraving and etching. This means that waterjet can be used to create custom logos, designs, or artwork on glass surfaces. Waterjet engraving is a popular choice for creating promotional items, such as branded drinking glasses or logoed signage.

What Are Some Common Applications For Waterjet Glass Cutting ?

Here are just a few examples of common applications for waterjet cut glass:

-Glass table tops

-Custom shower enclosures

-Cutting tempered or laminated glass

-Architectural features like skylights or privacy partitions

-Intricate decorative elements

No matter what the final application may be, waterjet cutting provides clean, precise cuts that give designers and homeowners the creative freedom to push the boundaries of what's possible with glass. If you are a business looking for a water jet-cutting service provider in Ontario, look no further. All Team Glass & Mirror Ltd. is one of the best names in the water jet-cutting business with decades of experience. We are also a leading glass manufacturer that supplies top-quality architectural glass and safety glass. Call us today to learn about everything we can do for you.