Differentiating 3 Common Types of Safety Glass

Do you own a business establishment or simply want to make everyone safe from a broken glass accident in your home? Then safety glass is the solution for you. This kind of glass can be made in different ways – varieties include wired glass, toughened glass, and laminated glass, all of which offer excellent mechanical intensity and impact resistance. Once smashed or hit by something hard it will not injure cause injury to loved ones or to your customers as the impact will not cause it to break into spiky, sharp shards. It is even fireproof.

Let’s Discuss the Different Types of Safety Glass and Their Differing Applications:

Wired glass: this type of safety glass is made by combining wire mesh with melted glass materials. It is fireproof and offers great compact resistance. What makes it unique is that once broken, the pieces will not break apart; instead, the cracked glass will just hang on the wire. It is usually used as a fireproof window and door, lighting roof, and as skylight windows in workshops.

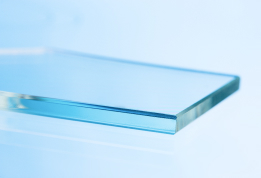

Laminated glass: what makes this variation a safety glass is the hyaloid plastic plates which are inserted into the glass. They are then heated, pressed together and bound, forming either a flat, curved or compound glass.

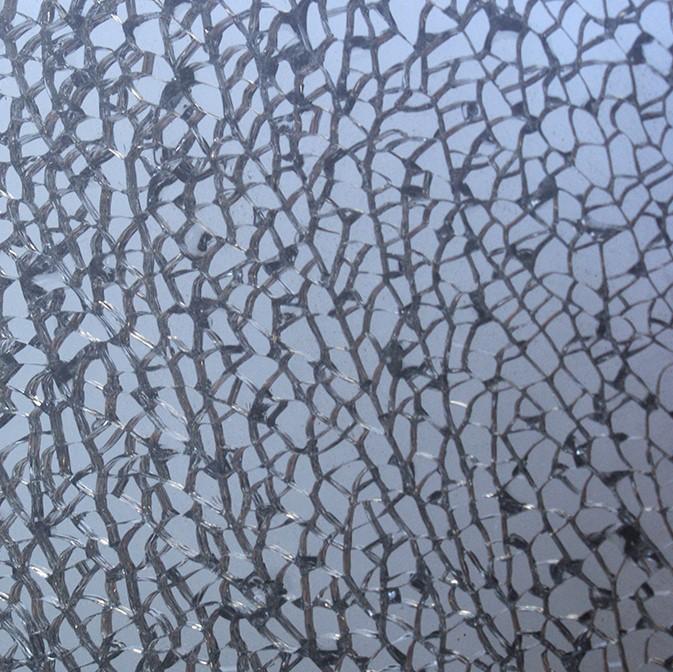

Toughened glass: this safety glass is made by heating a common flat glass at near-heat distortion levels, which is about 650°C. The heating gets rid of the inside stress and once properly heated, the glass is then cooled by cold wind produced from multiple jet nozzles. Once the desired room temperature is achieved, the toughened glass is now ready to use. It offers great properties such as high intensity, thermal stability, good security performance, and impact resistance. When smashed, the glass will only produce map cracking. Toughened glass is commonly utilized as curtain walls in high-rise buildings, partitions, windows and doors.

Get in touch with All Team Glass today for all your safety glass needs!