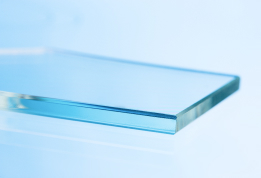

Steps Involved In Making Tempered Glass Panels

Glass is a widely used material. In today’s time, glass is used for numerous domestic and industrial applications. Tempered glass is one of the most common types used for industrial purposes. Glass manufacturers rely on a wide range of sophisticated tools and equipment to fabricate glass panels. There are various techniques used for fabricating tempered glass. Manufacturing tempered glass panels involve four main steps: cutting, heating, cooling, and laminating.

Processes Involved In Manufacturing Tempered Glass Panels

Cutting: Tempered glass is cut using a diamond saw or water jet cutter. It is important to make sure that the cuts are clean and straight in order to avoid any breaks or cracks during the tempering process. Diamond-tipped tools and other cutters like water and laser ensure that the glass can be cut without breaking.

Heating: The glass is then placed in a furnace and heated to temperatures around 1200 degrees Celsius. This step allows the molecules in the glass to realign and become stronger. Heating is an important aspect of manufacturing tempered glass.

Cooling: The next step is to rapidly cool the glass, usually by blowing air on it or dipping it in water. This sudden change in temperature makes the outer surface of the glass harder than the inner core, which gives the tempered glass its strength.

Laminating: Finally, the tempered glass is laminated with a plastic film. This helps to hold the glass together if it shatters and also makes it safer to use in areas where there is a risk of breakage.

It is essential you source tempered glass panels from a leading brand like All Team Glass & Mirror Ltd. We are one of the leading names when it comes to glass manufacturing. We also manufacture and supply the best architectural glass and safety glass. Get in touch with us today to learn about everything we can do for you.